Possibly the biggest surprise people see when they visit Eagles Rise is the small size of the boutique winery. Currently we use only around 50% of the grapes we grow, so we have a secure expansion pathway as demand continues to grow. But as any man would say, “don’t let the size fool you” – it is very effective.

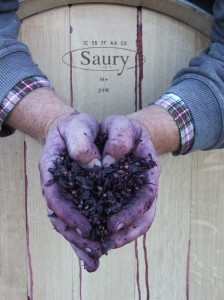

None of the stainless steel vats are larger than 2,000 litres so each parcel of grapes gets individual personalised attention. Our crusher-destemmer can be lifted by one person and when gravity feed isn’t available, the pumps only flow at 25lt a minute. All reds are pressed off skins using an old hand operated ratchet basket press. Its hard work for a single person, but it offers unparalleled control over tannin and phenolic extraction levels, when we ‘separate the margins’ for later final blending. For more urgent processes like the immediate pressing of dark skinned Pinot Gris grape within 10 minutes of hand picking to extract the clear juice before pigmentation, I hire an airbag press for a day, and likewise hire a wine filtration system for two days year.

All bottling, labelling and packaging is done onsite by our own family. Up until the 2017 vintage we exclusively use premium Australian made bottles, and cork closures (with guaranteed no cork spoilage), which are reported as being over 30 times more sustainable than their nearest alternative. The 2017 vintage was our first use of screw caps. The insulated and air conditioned building is filled with racks of premium French Oak 225lt barriques and 300lt hogshead barrels, however only a few cases of finished wine are kept on-site at any one time. The main case stock is held in a secured temperature controlled warehouse to allow the wines to age and mature the traditional old fashioned way (no industrial chemicals or shelf life reducing micro-oxygenation) and when just right, released to the public to share, enjoy and talk about.